What are the typical dimensions of aluminum bar gratings used in New York?

Table of Contents

Features of Aluminum Bar Gratings

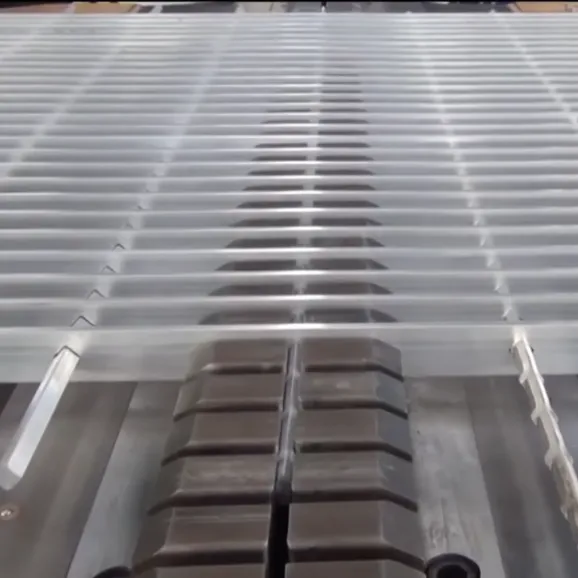

Aluminum bar grating is widely used in New York due to its exceptional versatility, strength, and corrosion resistance, making it an ideal choice for a broad range of applications. These include walkways, ramps, platforms, drainage covers, mezzanines, stair treads, and trench grating. Aluminum grating is known for its lightweight properties, ease of installation, and low maintenance, making it suitable for both indoor and outdoor settings, especially in areas exposed to harsh weather conditions and heavy foot traffic.

Construction Types and Customization Options

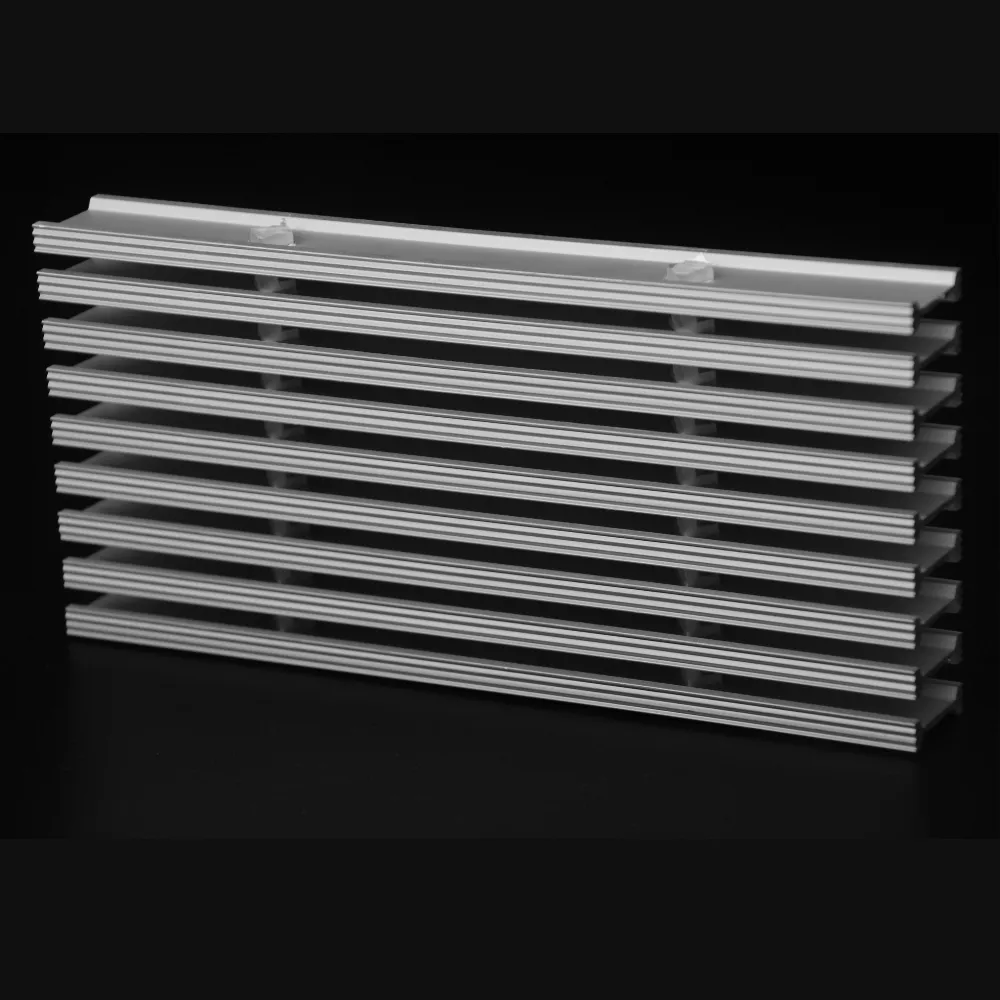

The typical specifications for aluminum bar grating cater to different project needs and include various construction types such as swaged, I bar, press locked, and flush top designs.

Each type provides unique benefits:

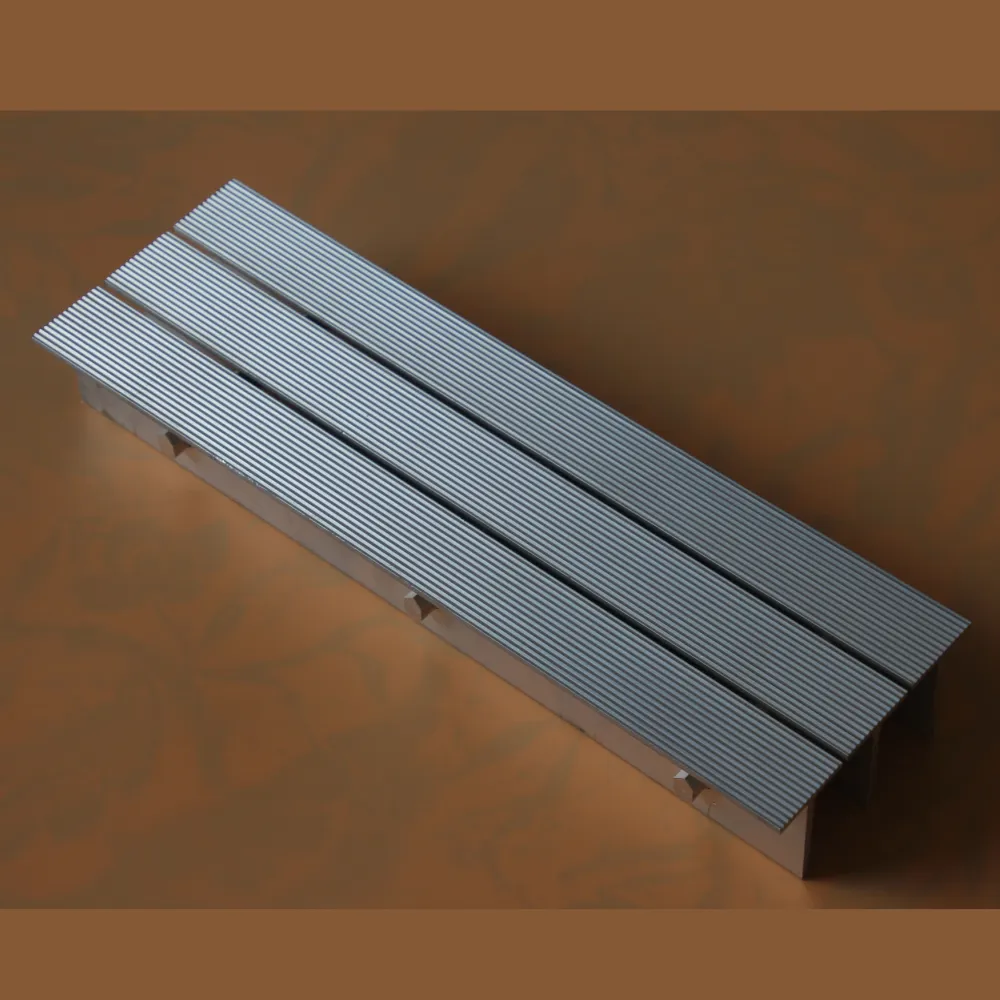

Swaged Grating: Offers a sleek appearance and is ideal for applications where aesthetics and safety are paramount.

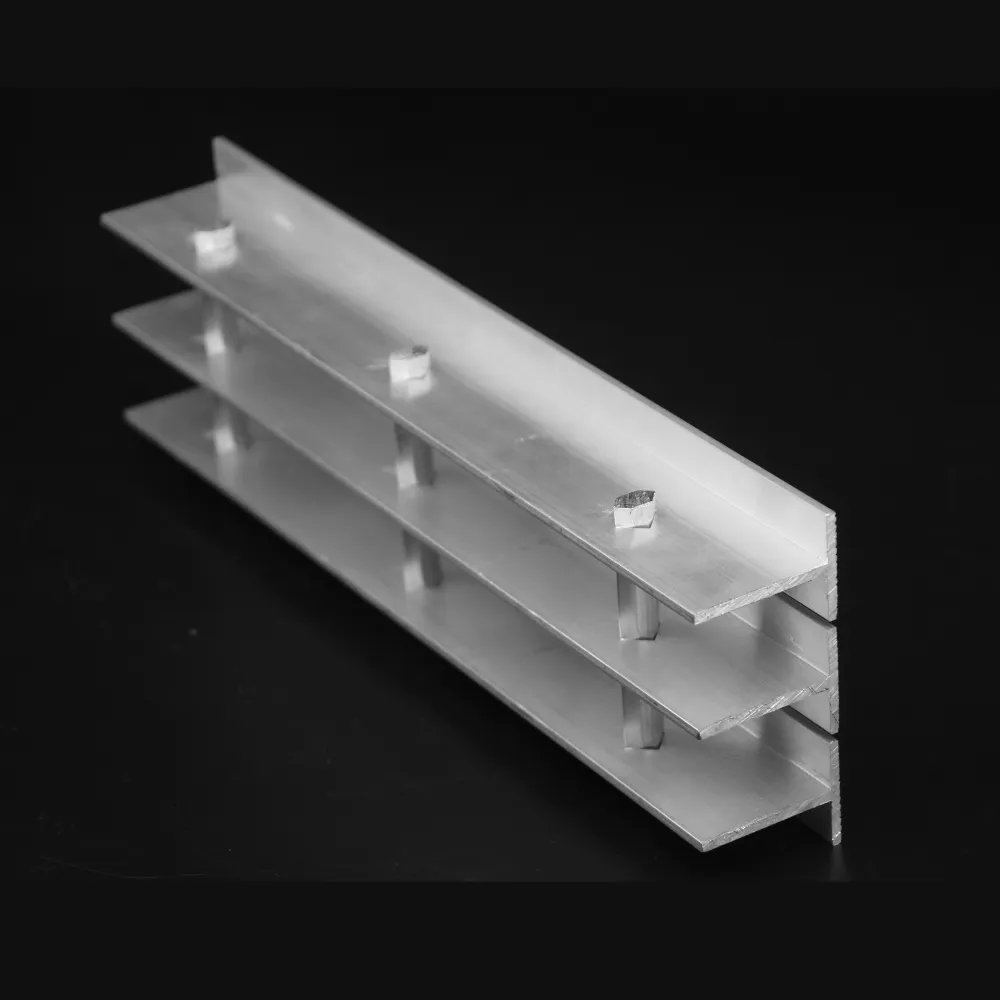

I-Bar Grating: Features a unique shape that reduces weight without compromising load-bearing capacity, making it perfect for environments where both strength and cost-efficiency are crucial.

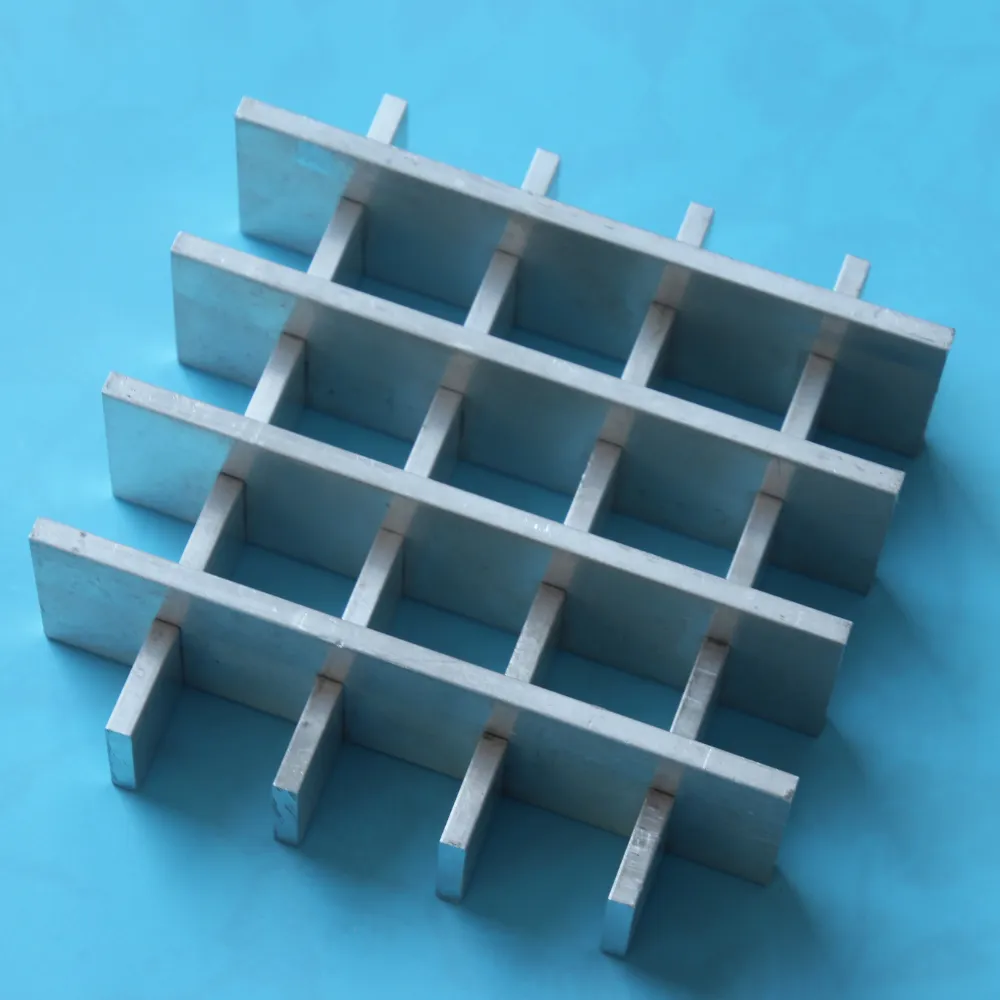

Press-Locked Grating: Ensures a tight, secure fit for industrial applications requiring maximum strength and durability.

Flush-Top Grating: Provides a smooth walking surface, making it suitable for pedestrian areas.

These diverse construction types allow for a high degree of customization, enabling architects and engineers to select the most appropriate design that meets specific performance criteria and project requirements.

Dimensions and Spacing Standards

Aluminum bar grating comes in various dimensions to suit specific load and spacing needs. The most common bearing bar spacing is 19-4, which translates to 1-3/16” between bearing bars and 4” between cross rods. Additionally, options are available for cross bar spacings of 2″ or 4″ on center. The bearing bar spacing can range from 19/16″ to 7/16″ on center, depending on load requirements and design preferences.

This flexibility ensures that the grating can accommodate different load capacities, from light pedestrian traffic to heavy vehicular loads.

Variety in Sizes and Compliance with ADA Standards

The aluminum grating is available in a range of sizes, with bearing bar widths typically offered in 11/16”, 5/8”, 1/2”, and 7/16”. Thicknesses generally range from 1/8” to 3/16”. Importantly, aluminum grating with a maximum opening of 1/2” conforms to the Americans With Disabilities Act (ADA) guidelines when installed correctly, providing safe and accessible pathways for people with disabilities.

Specialized Options for Embedded Applications

For applications requiring embedded concrete installations, extruded aluminum grating frames are available. These frames enhance the adaptability of aluminum grating in construction projects, providing a robust and seamless integration into concrete structures. This feature is particularly beneficial in environments such as industrial facilities, commercial complexes, and public infrastructure projects.

Materials and Durability for Challenging Environments

Manufactured using high-quality aluminum alloys, such as ASTM B-221, 6063, or 6061, aluminum bar grating demonstrates excellent durability, strength, and corrosion resistance. These materials are specifically chosen for their suitability in harsh environments like water treatment plants, chemical processing facilities, and the marine industry. The inherent properties of these alloys allow the grating to withstand exposure to moisture, chemicals, and extreme temperatures, thereby extending the lifespan and reducing long-term maintenance costs.

Conclusion

Aluminum bar grating is an essential component in New York’s architectural and industrial landscape, providing strength, versatility, and a high level of customization for a wide range of applications. Whether used in pedestrian walkways, industrial platforms, or drainage systems, its adaptability, compliance with safety standards, and ability to endure challenging conditions make it a reliable and cost-effective choice for both new constructions and renovations.

Contact Us

For more information about our aluminum bar grating products or to request a quote, please contact us. Our team is here to assist you with any inquiries and provide expert solutions for your project needs.

Comments

Tags

Frequently Asked Question

Aluminum bar grating is significantly lighter than steel, which makes it easier to handle and install, reducing labor costs and installation time. It also offers superior corrosion resistance, especially in environments with high humidity and exposure to winter salts, common in New York. This leads to a longer lifespan and lower maintenance costs compared to steel.

Aluminum is non-magnetic and non-sparking, making it a safer choice in environments where flammable materials or electrical safety is a concern. Additionally, its excellent slip resistance and effective drainage properties make it ideal for high-traffic areas, reducing the risk of accidents.

Yes, aluminum is 100% recyclable without losing its properties, making it an environmentally sustainable choice. Using aluminum grating supports green building practices and can contribute to LEED certification, aligning with New York’s focus on sustainable urban development.

Aluminum bar grating requires minimal maintenance due to its corrosion resistance and durability in harsh conditions. Unlike steel, it does not rust, even in wet or salty environments, meaning it doesn’t need frequent painting or coating, resulting in reduced long-term maintenance costs.