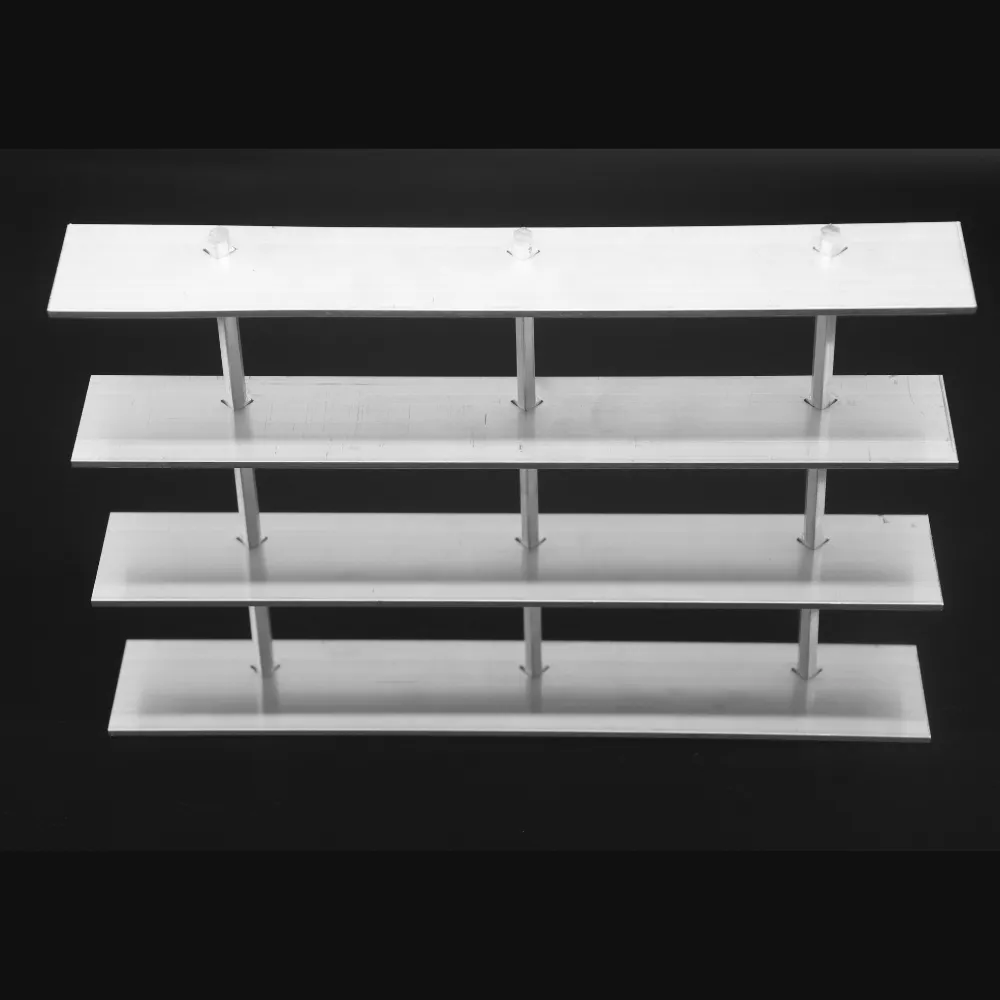

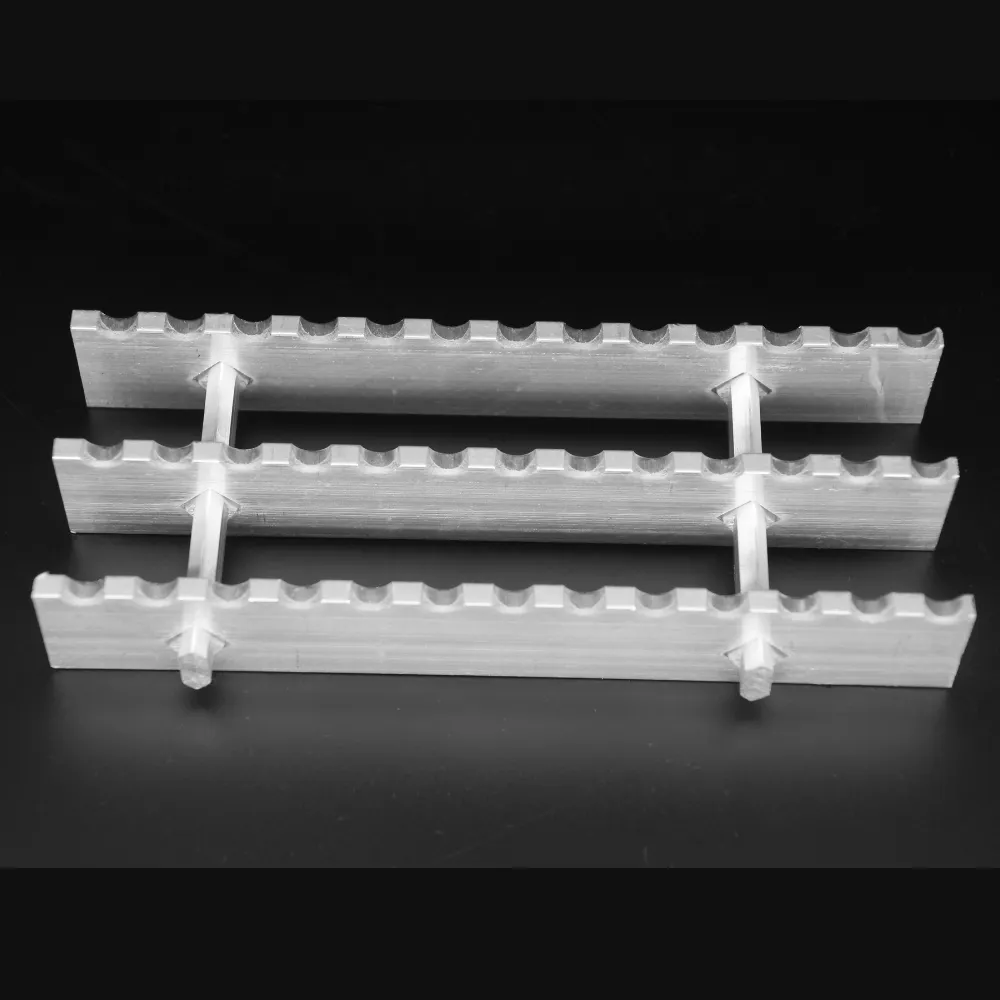

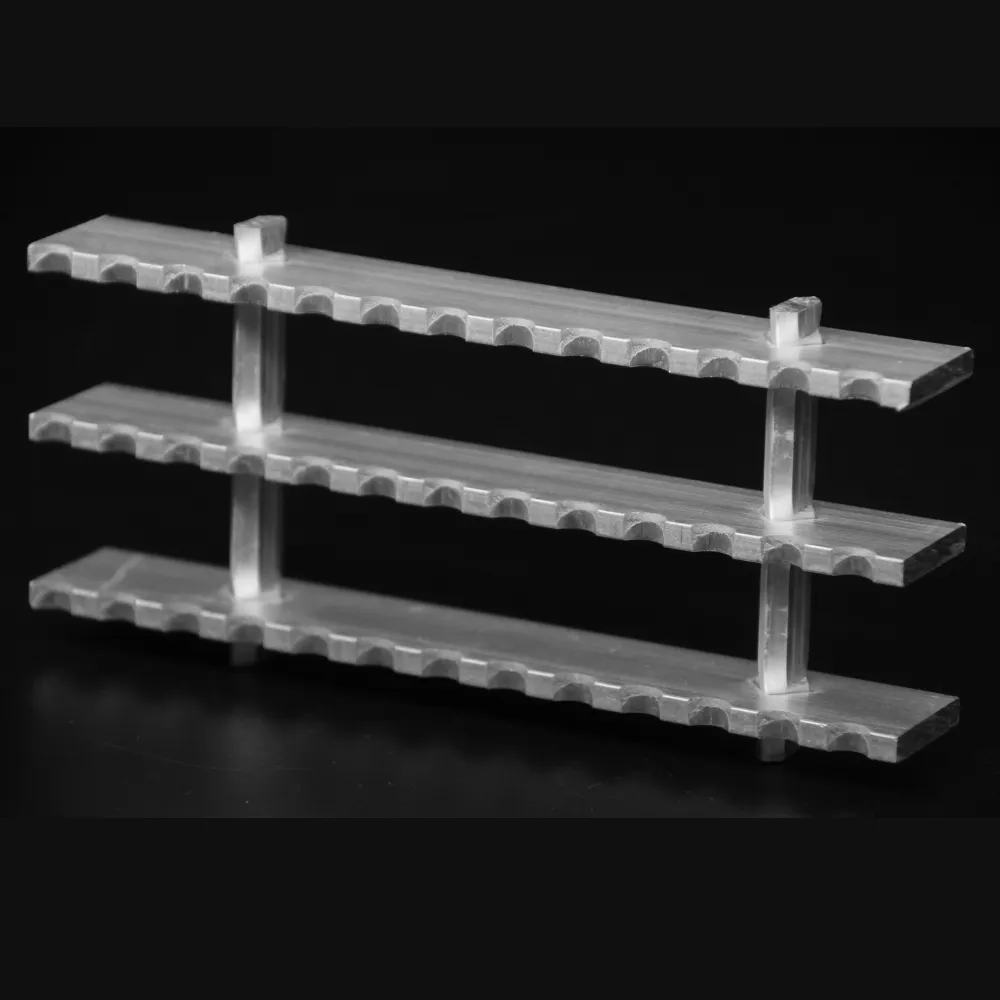

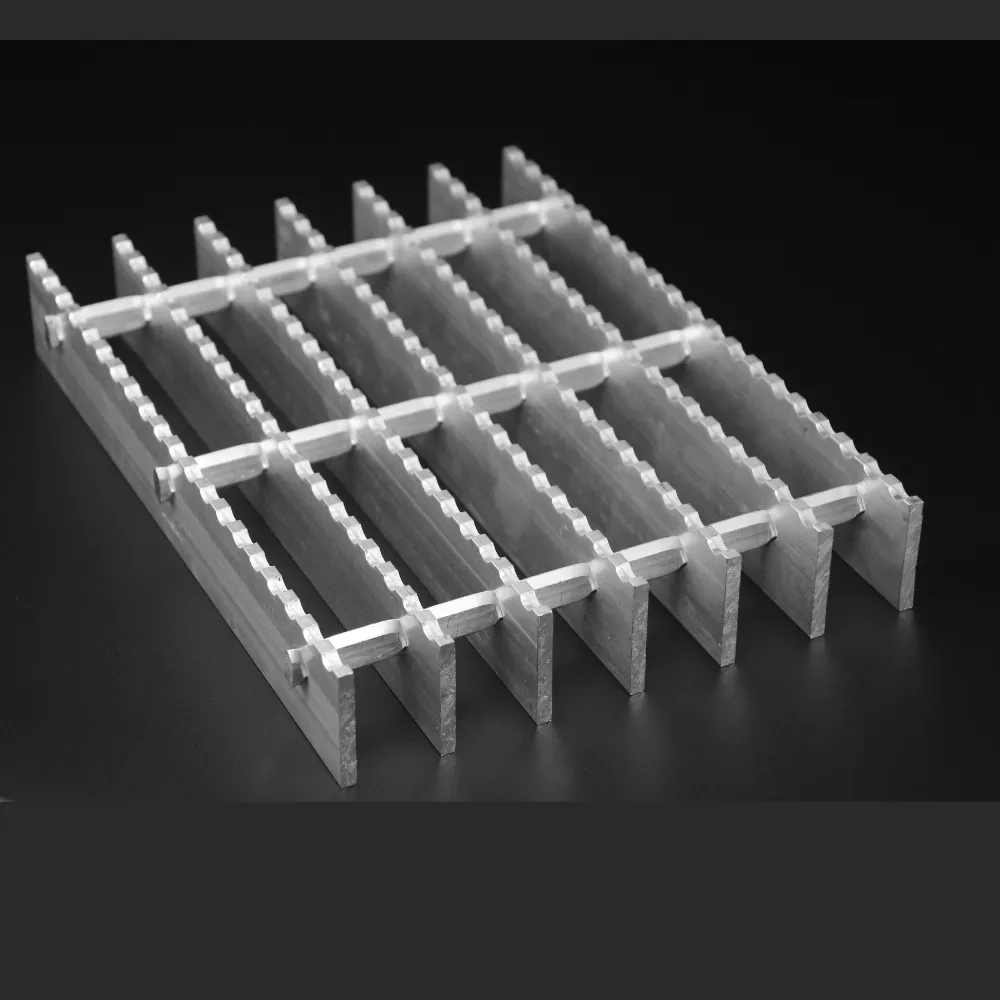

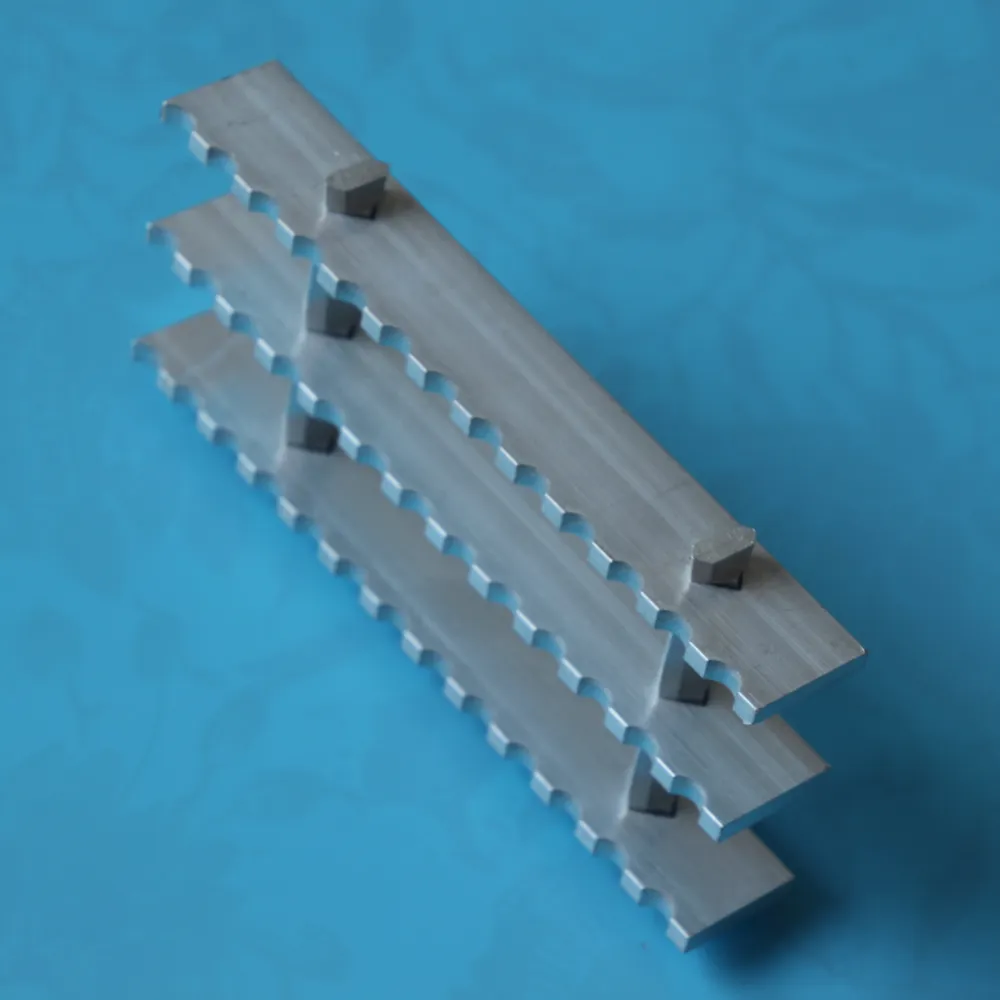

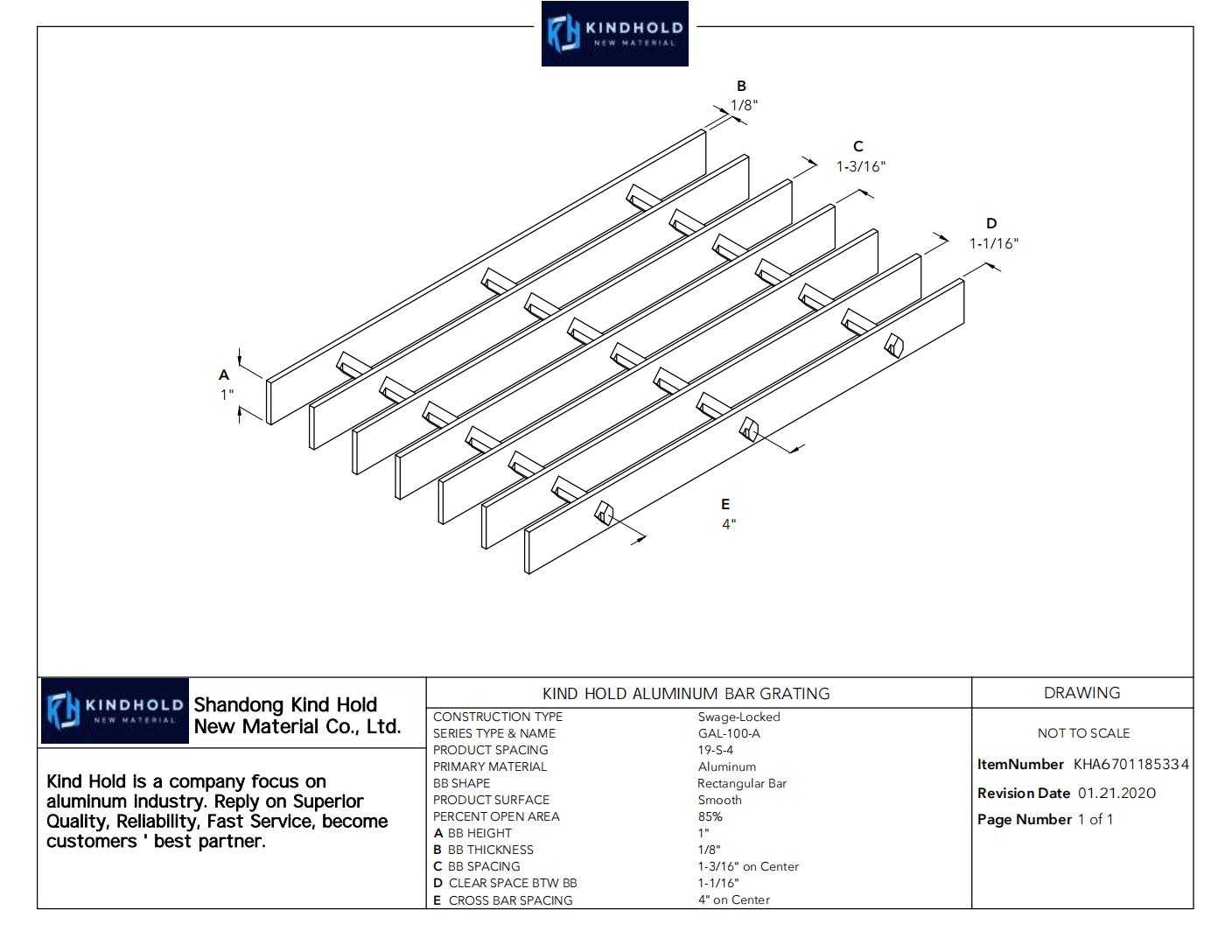

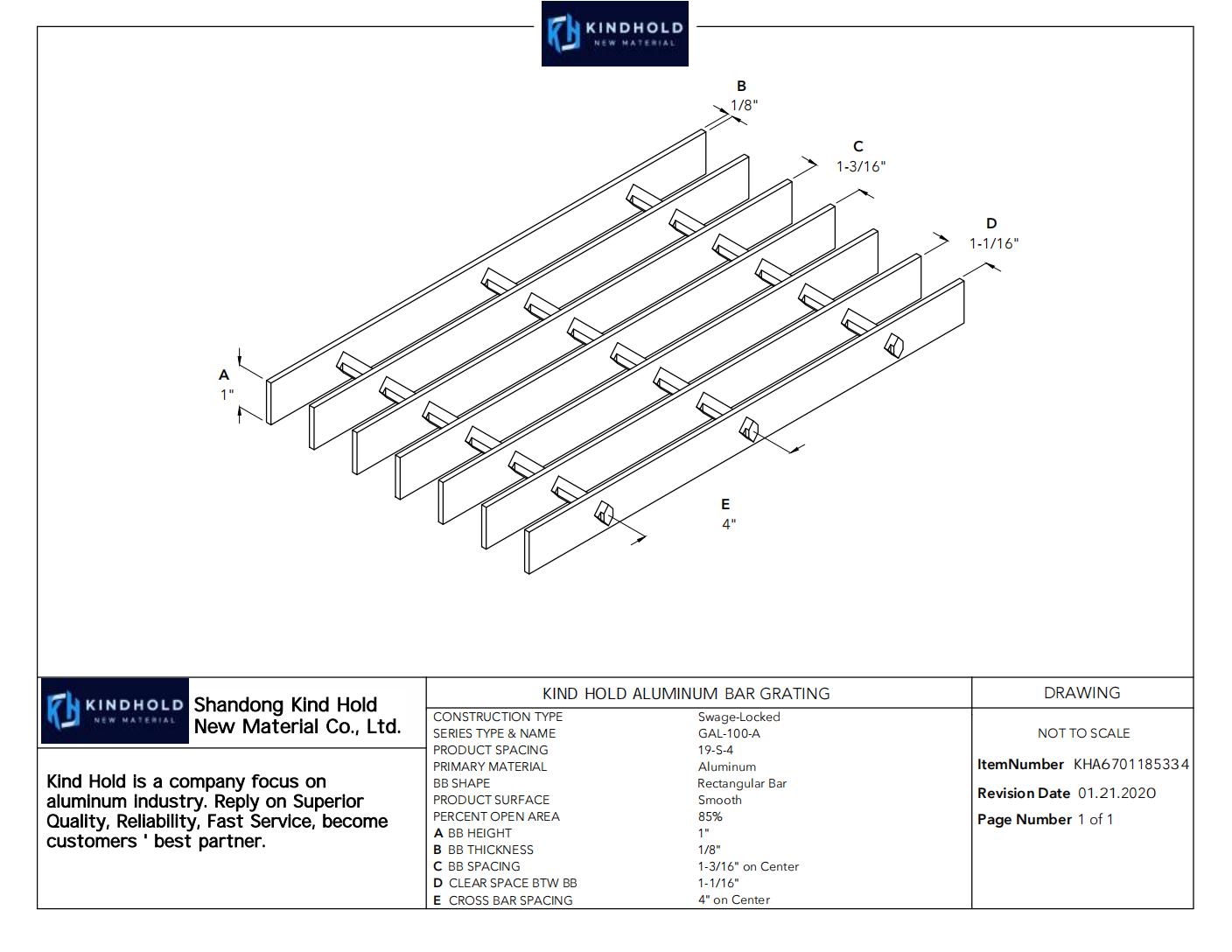

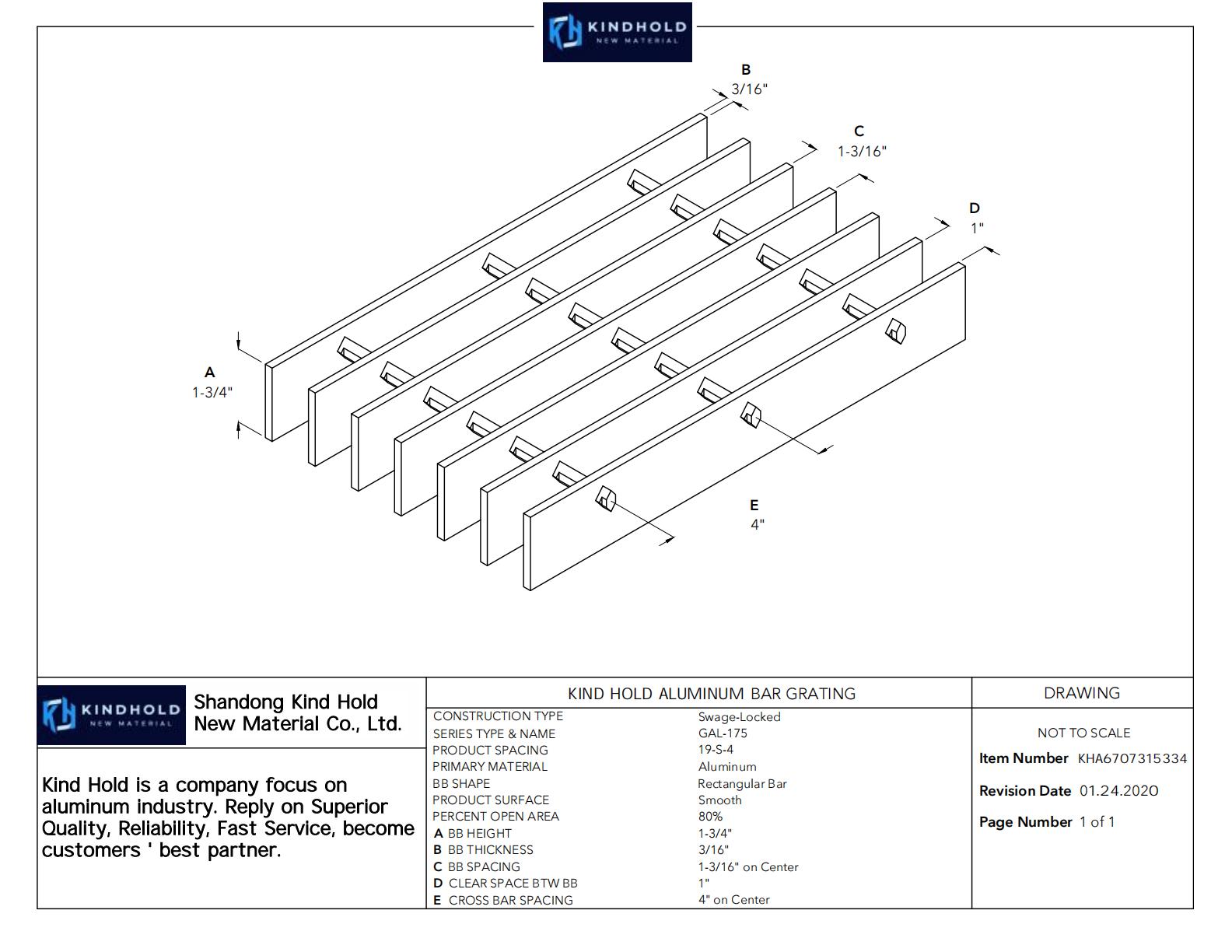

Need Loadtable of aluminum gratings and drawings of aluminum gratings?

We offer a comprehensive range of load tables and detailed drawings of aluminum gratings available for download. Whether you’re an engineer or a project manager, our extensive resource library will assist you in easy selection and design. Contact us now to receive the professional support and complete documentation you need!